Then I rip thin strips of usually contrasting wood the thickness needed to fill the saw cuts.

The tenon jig worked perfectly, making splines with very parallel sides and exactly the same thickness every time.įor "across the corner" splines like shown in Robert's second picture, I have usually used a shop made jig in my table saw to hold the box corner down while cutting across the corner with the table saw,with the box and jig held against the fence to cut in the correct position. Since I am making four boxes, I needed to go back to the Unisaw three more times to get enough splines for all four corners of all four boxes. What is usually the resulting tenon on each end of the board became scrap.

Miter spline jig plans free#

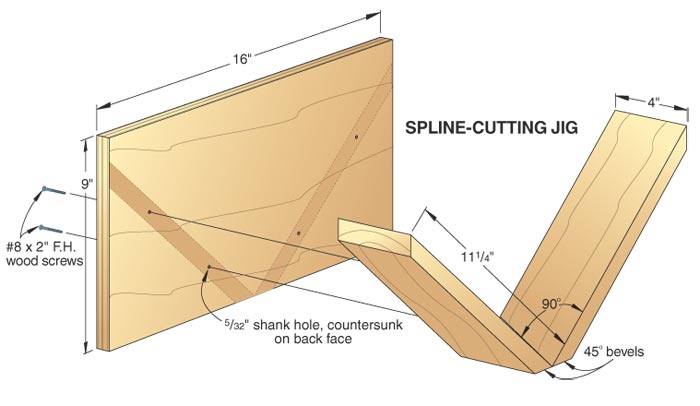

Using a stop set on my miter saw, I then cut the splines free from the board at just the right width. Then I flipped the board end for end and cut two more splines on the other end of the board. The spline was actually cut from the surface of the board, so I could flip the board horizontally and make another spline from the back surface of the board. Then I used my Delta Tenon jig, positioned so as to cut cross grained splines from the end of a board. I made a jig to ride in the miter slot to hold the previously mitered boards at 45 degrees while I cut the slots for the splines. My recent mitered splines were like picture #1 in Robert's post #14. Give you better control/zero clearance for chip out control I don't see these in the store bought version. If you make a jig/sled, consider replaceable inserts where the cutter will come through. Perpendicular can be made on the router table, possibly with the same sled if miter bar locations allow for it or if it can be adjusted.

Dados can be made by tipping the straight blade but some additional chisel work is required. Straight cuts can be done with a rip blade as stated by others. Perpendicular can be done on the table saw with a jig/sled that holds the assembled joint at 45 degrees. Or on a table saw with a sled that holds the wood 45 degrees to the 90 degree blade position. Parallel can be done on the table saw with blade tilted 45 degrees with a miter gauge and stop blocks. One is parallel to the joint, the other perpendicular. I am pretty sure they can be done with either piece of equipment but thought a 'picture' might be worth those 1000 words.

0 kommentar(er)

0 kommentar(er)